Alignment Before Action: Getting Operational Definitions Right

Never assume "everyone knows" what something means or how it is measured or defined.

Hi friends,

Let’s not waste time, because this week, we’re talking about something that might seem small but has the power to quietly wreck your entire improvement effort.

Operational definitions.

Yes, I know.

It is not the sexiest topic, I'll admit. But ignore this, and you might as well be measuring with a “rubber ruler”.

So, what is it?

An operational definition is a clear, agreed-upon way to measure something.

It tells you exactly what you’re measuring, how you’re measuring it, and when the measurement starts and ends.

In improvement projects, especially in the Measure phase, this is gold. It’s the only way to be sure everyone is speaking the same language. Because if we don’t agree on what we’re measuring, we’ll all be chasing different ghosts.

Here’s how things go sideways…

Let’s say you’re trying to reduce the Length of Stay in a hospital.

Sounds easy, right?

But wait. Are we measuring from when the patient walks into A&E? Or from when they get assigned a bed? Or maybe from when the first doctor sees them?

Do we include time spent waiting for test results? Or transfers between departments?

You see the problem?

If Nurse A measures from check-in, and Nurse B measures from first medication, you’re not comparing apples and oranges, you’re probably comparing apples and yams.

Another instance

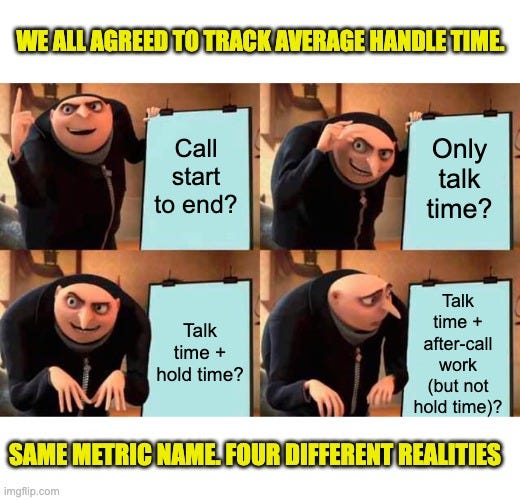

Take a call centre tracking "Average Handling Time":

Scenario 1: Measures from call connection to disconnect

Scenario 2: Measures only active talk time

Scenario 3: Includes after-call work but not hold time

Now your "data" is a mess, and your "improvements" are just guesses.

All reports have the same metric name. None are measuring the same thing. Now imagine making staffing decisions based on this "data."

Here’s what to keep in mind when defining and measuring your metrics:

Start and End Point: Be specific. When exactly does the process start and when does it stop? Don’t assume everyone knows.

Consistency: Make sure the same definition is applied every single time. If you change the rules midway, your data is cooked.

Customer Perspective: Ask yourself, what would matter most to the end-user? What would they value? That’s often a good guide for your definition.

Don’t measure shadows: If you can’t clearly explain what a number means and how it was measured, throw it out, choose a different metric for your improvement or define it better.

The Golden Rule

Never assume "everyone knows" what something means or how it is measured or defined.

That’s how people end up measuring rice with teaspoons.

Write it down. Agree on it. Then measure.

Final Thoughts

Improvement starts long before the fancy charts and colourful dashboards. It starts with defining exactly what you’re measuring clearly, consistently, and in a way everyone understands.

If your definition is vague, your data will be too, and if your data is confused, your improvement efforts will be chasing shadows.

A wise man once said, “You cannot improve what you do not measure.”

I’ll take it a step further: “If you cannot define it, you cannot measure it. And if you cannot measure it, forget about improving it.”

So, the next time someone says “but that’s obvious,” or “everybody knows what that means”, hand them a pen and ask them to write it down.

Then sit back and enjoy the awkward silence.

Until next time, keep improving

– Tomiwa

Process Improvement Enthusiast