The 8 Lean Wastes: Practical Examples You’ll Recognize in a Heartbeat

Value and waste are two sides of the same coin: minimizing waste increases the potential to deliver value, and focusing on value helps expose and eliminate waste.

Good day, my friend!

Let me start with an apology. This post has been long overdue. When I kicked off this newsletter, I shared about the Core Concepts of Lean and the definition of Value. Naturally, I thought I’d also covered the concept of Lean Waste. But, as they say, better late than never, right?

So today, let’s talk about Lean Waste—the ultimate spoiler in any efficient process.

What is Value vs. Waste?

Here’s the gist:

Value is anything the customer is willing to pay for because it directly satisfies their needs or solves their problems. It’s the hot, delicious pizza made just the way they like it or ordered it, the reliable and instant bank transfer when they need it most, or the fast and uninterrupted network connection during an important video call. It’s the essence of what the customer truly values.

Waste, on the other hand, is everything that doesn’t contribute to that core value. It’s the burnt crust or soggy base on a pizza, the hours spent waiting for a bank transaction to go through, or the network disruptions that leave you saying, “Hello? Can you hear me?” These things don’t add value but still consume resources, time, or energy.

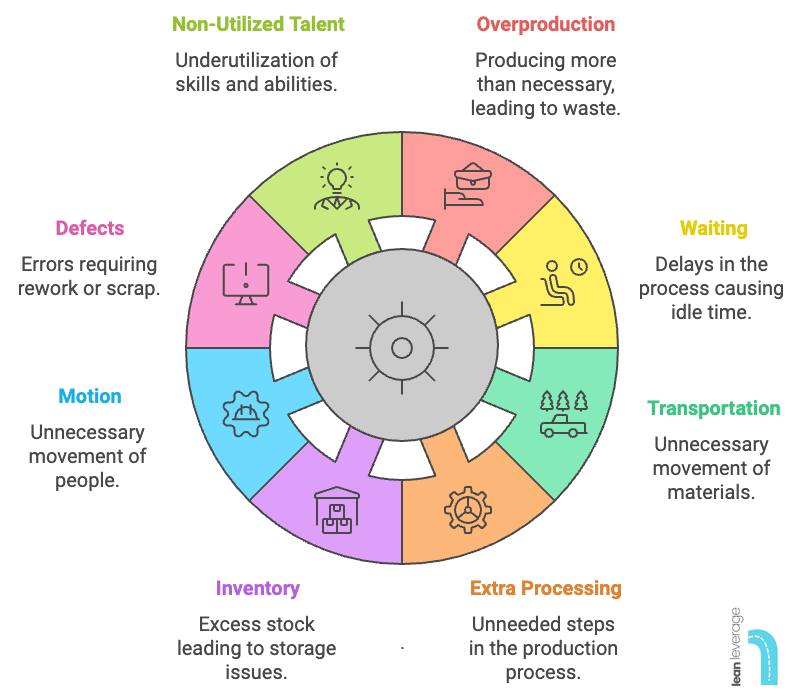

The 8 Wastes of Lean- (D O W N T I M E)

Let’s break this down using different examples that you would definitely be able to relate to. To make it easy to remember, Lean uses the acronym DOWNTIME:

1. Defects

Mistakes that need fixing.

Example: That classic "What I ordered vs What I got" situation. You order a sleek pair of sneakers, and they deliver something that looks like your grandpa's orthopedic shoes.

2. Overproduction

Doing more than is needed.

Example: Living alone without a freezer and deciding to cook a massive pot of stew. By day three, the stew is a science experiment, and you’re tossing it all out.

3. Waiting

Time wasted while nothing happens.

Example: Spending two hours in the ATM queue because "only one machine is dispensing cash," and the network is on leave without pay.

4. Non-utilized Talent

Not using people’s skills effectively.

Example: Asking your software developer intern to go and buy rice because they’re new, instead of letting them fix that Excel formula that’s been stressing you since Monday.

5. Transportation

Unnecessary movement of items.

Example: Going to the market three times in one day because you keep forgetting something. By the third trip, even the market women are calling you “customer of the year.”

6. Inventory

Too much of something that’s not immediately needed.

Example: Stocking up on expensive fruits and veggies, then letting half of them rot in the fridge. This one really hits in Tinubu’s economy—“rich people problems,” indeed.

7. Motion

Unnecessary movement of people.

Example: Searching for your car keys, AirPods, and wallet every morning because you’ve refused to buy a key holder. Now, you’re late to work... again.

8. Excess Processing

Doing more work than necessary.

Example: Printing a 10-page document in color when black-and-white would’ve done the job. Now your printer is angry, and so is your wallet.

What is the Relationship between Value and Waste?

Some might argue that Value cannot be viewed in isolation of waste and vice versa. Just as how we might say light is the absence of darkness and vice versa.

This angle is insightful and there’s some truth to it. Here is how they relate.

Value isn’t just the absence of waste:

It is what the customer is willing to pay for and is created through processes that contribute to fulfilling the customer’s needs.

Waste is anything that doesn’t add value. Eliminating waste does not guarantee value always, it just removes obstacles. As a baker, improving the delivery of your cakes may allow you deliver your cakes quicker, but if the cake is still rubbish, you have not given value to your customer.Waste isn’t just the absence of Value:

Certain "wastes" might be necessary—like regulatory paperwork or routine maintenance. They don’t directly add value, but they keep the system running smoothly.

Why Understanding Waste Matters

By identifying value, you know what you’re aiming for. By spotting waste, you clear the obstacles blocking your path. The two concepts work hand in hand to create processes that are not just efficient but also meaningful. It’s that Simple!

Until next time,

Tomiwa.

Lean Process Improvement Enthusiast (remember DOWNTIME—it’s not just an acronym; it’s a cheat code for Lean success)